DB-200

Design for Advanced Thinning Substrate Solution

“Dual Stage/Carrier transfer, Bottom CCD position, flexible load-unload design as BEST system combination solution”

Warpage ≦10 mm

Advanced thinning substrate might cause higher warpage

Carrie-car design transferring easy to get over high warpage substrate

Enhance accuracy design with outstanding throughput performance

Bottom V.P.S(Vision Position System) enhance marking accuracy within ± 0.05mm

Dual Stage/Carrier design performance outstanding throughput

Change over time < 10min

High Flexibility load-unload design

Design for both Stack, Slot magazine loader, available for OSATs current product line

|

|

|

|

|

|

|

|

|

|

|

|

*Panel – 300mm*300mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

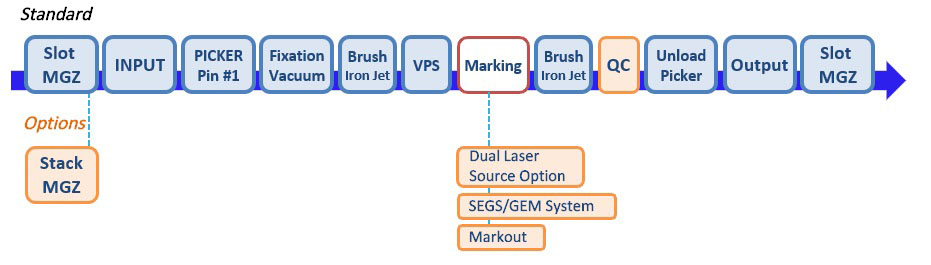

DB-200 Process Flow